Product Comparison Table

Safety Features

Product Family

Motor Braking

What is Motor Braking?

Our patented electronic brake makes your machine stop in seconds! Learn More

Anti-Restart

What is Anti-Restart?

Anti-restart is an OSHA-required feature of EVERY motor-driven machine in a workplace. Learn More

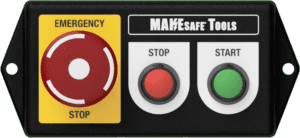

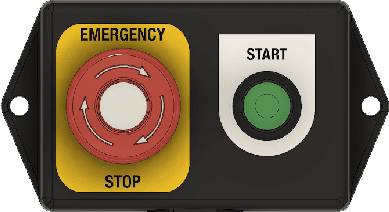

E-Stop

OSHA Compliant

Voltages & Max HP

Voltage & Horsepower Ratings?

Each of our models is rated for a specific voltage and a maximum motor size. Learn More

1ϕ 120V

1ϕ 240V

3ϕ 240V

3ϕ 480V

3ϕ 600V

PTB

✔

✔

✔

✔

1.5 HP

3.0 HP

5.0 HP

–

–

PTC

–

✔

✔

✔

1.5 HP

3.0 HP

5.0 HP

–

–

IMB

✔

✔

✔

✔

10 HP

20 HP

40 HP

100 HP

100 HP

IRE

–

✔

✔

✔

10 HP

20 HP

40 HP

100 HP

100 HP

Still not sure which model you need? Check out our guide.

Power Tool Brake

Model Number Prefix

Rated Input Voltage

Rated Horsepower (UL508)

Rated Current (UL508)

Approvals

Connector Type

Dimensions

Weight

User Manual

PTB-V120-P1

1ϕ 120 VAC, 60 Hz 1

1.5 HP

NEMA 5-152

PTB-V240-P1

1ϕ 240 VAC, 60 Hz 1

3.0 HP

NEMA 6-152

PTB-V240-P3

3ϕ 240 VAC, 60 Hz 1

5.0 HP

NEMA L15-202

15A

UL508A: Industrial Control Panels

UL508A: Industrial Control PanelsCSA #14-13: Industrial Control Equipment

7.25” L x 5.0” W x 2.22" H

(185 mm x 127 mm x 57 mm)

(185 mm x 127 mm x 57 mm)

4 lbs (1.9kg)

1 50Hz options are available for international customers.

2 Custom plug types and cable terminations available, including international options.

2 Custom plug types and cable terminations available, including international options.

Power Tool Control

Model Number Prefix

Rated Input Voltage

Rated Horsepower (UL508)

Rated Current (UL508)

Approvals

Connector Type

Dimensions

Weight

User Manual

PTC-V120-P1

1ϕ 120 VAC, 60 Hz 1

1.5 HP

NEMA 5-152

PTC-V240-P1

1ϕ 240 VAC, 60 Hz 1

3.0 HP

NEMA 6-152

PTC-V240-P3

3ϕ 240 VAC, 60 Hz 1

5.0 HP

NEMA L15-202

15A

UL508A: Industrial Control Panels

UL508A: Industrial Control PanelsCSA #14-13: Industrial Control Equipment

7.25” L x 5.0” W x 2.22" H

(185 mm x 127 mm x 57 mm)

(185 mm x 127 mm x 57 mm)

3 lbs (1.9kg)

1 50Hz options are available for international customers.

2 Custom plug types and cable terminations available, including international options.

2 Custom plug types and cable terminations available, including international options.

Industrial Machinery Brake

Model Number Prefix

Input Voltage

Rated Horsepower

Approvals

Enclosure

Safety Rating

Power Connections

Dimensions

Weight

User Manual

These units are built to order and can be made to any specification.

Standard sizes are denoted by their model number suffix (e.g. HP1=1.0 HP, HP5=5.0 HP).

For example: Model "IMB-V240-P3-HP5" is rated for 5.0HP.

Standard sizes are denoted by their model number suffix (e.g. HP1=1.0 HP, HP5=5.0 HP).

For example: Model "IMB-V240-P3-HP5" is rated for 5.0HP.

UL508A: Industrial Control Panels

UL508A: Industrial Control PanelsCSA #14-13: Industrial Control Equipment

NEMA-rated polycarbonate/fiberglass composite enclosure. Includes mounting brackets.

single-channel (standard)

customer specified safety performance level (optional)

customer specified safety performance level (optional)

field connection to internal terminal blocks (standard)

pre-wired with 6′ SO cord (optional)

pre-wired with 6′ SO cord (optional)

15.25″ x 13.25″ x 7.75″ (388 mm x 337 mm x 197 mm)

Approx. 35 lbs. (16 kg)

IMB-V120-P1

1ϕ 120V

IMB-V240-P1

1ϕ 240V

IMB-V240-P3

3ϕ 240V

IMB-V380-P3

3ϕ 380V

IMB-V480-P3

3ϕ 480V

IMB-V600-P3

3ϕ 600V

Industrial Anti-Restart & E-Stop System

Model Number Prefix

Input Voltage

Rated Horsepower

Approvals

Power Connections

Dimensions

Weight

User Manual

These units are built to order and can be made to any specification.

Standard sized are denoted by their model number suffix (e.g. HP1=1.0 HP, HP5=5.0 HP).

For example: Model "IRE-V240-P3-HP5" is rated for 5.0HP.

Standard sized are denoted by their model number suffix (e.g. HP1=1.0 HP, HP5=5.0 HP).

For example: Model "IRE-V240-P3-HP5" is rated for 5.0HP.

UL508A: Industrial Control Panels

UL508A: Industrial Control PanelsCSA #14-13: Industrial Control Equipment

Standard models are provided with 6′ SO cord on power input and power output.

8″ x 8″ x 7″

Approx. 16 lbs. (7 kg)

IRE-V120-P1

1ϕ 120V

IRE-V240-P1

1ϕ 240V

IRE-V240-P3

3ϕ 240V

IRE-V380-P3

3ϕ 380V

IRE-V480-P3

3ϕ 480V

IRE-V600-P3

3ϕ 600V

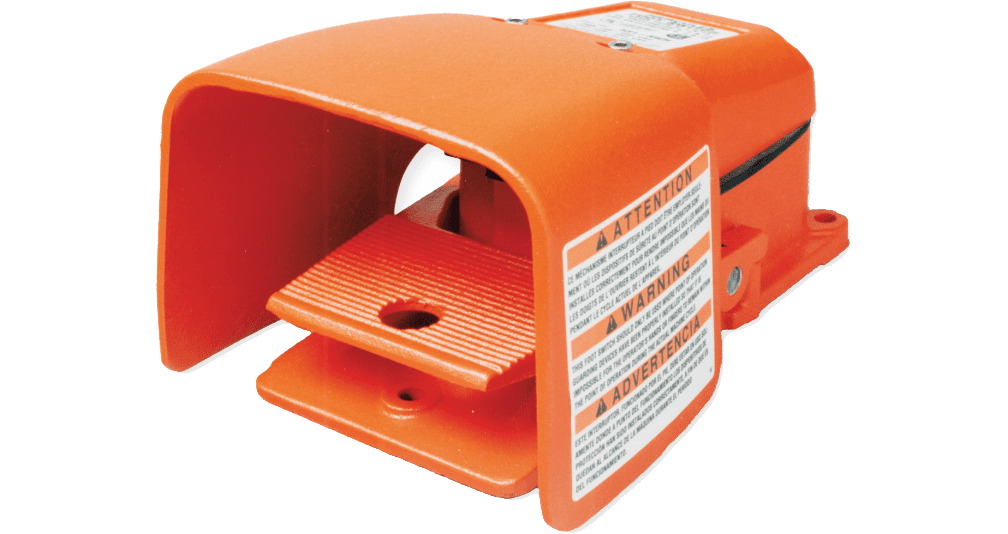

All standard orders include the following items:

Optional control substitutions:

Document Downloads

(click to download)