Risk Assessment

A band saw risk assessments always includes a core set of recognized hazards and requirements. The discussion below describes each hazard, points out the related OSHA requirements, and makes suggestions for remediation.

While the discussion below addresses the most common hazards, a machinery risk assessments should also include an investigation of application-specific hazards.

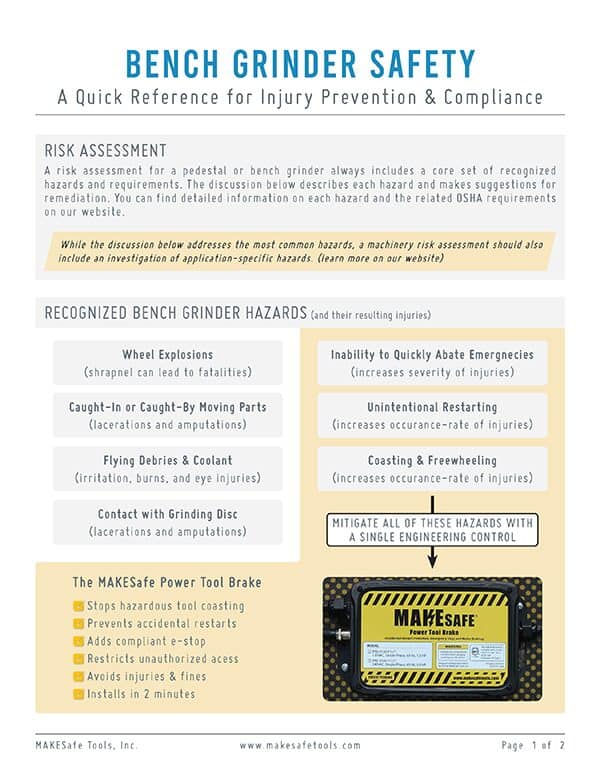

Recognized Band Saw Hazards

Click on any of the hazards below to learn more about the hazard, how it causes injury, and any related industry standards or requirements.

Coasting & Freewheeling

Industrial machines coast and continue to spin long after they have been turned off. This coasting (or "freewheeling") can last for minutes and puts machine operators at risk as they continue to work around the still-operating machinery. Learn More.

Unintentional Restarting

Automatic and unintentional restarts happen when power is lost while a machine is operating. The machine then starts itself when power is restored. This is a specialized case of hazardous energy control but one that is not solved with typical lock out tagout procedures. That is why OSHA, ANSI, NFPA, NEC, and CSA all explicitly require means to prevent

the unintentional restarting of machinery. Learn More.

Getting Caught-In or Caught-By Moving Parts (Nip Points)

A nip point hazard is created whenever two adjacent parts of machinery move towards each other and have the potential to capture or draw-in foreign objects like body parts, loose clothing, or hair. These hazards are especially problematic because this type of motion tends to grab and pull an operator towards the hazard, thereby increase the severity of any incident. This is why OSHA has specific requirements for blade guards and covers for shafts and belts on band saws. Learn More.

Contact with Blade

Contact with a blade can quickly lead to lacerations, and amputation. This hazard is especially significant on band saws due to how close an operator hands come to the blade during some operations.

Band Saw Mitigations and Safeguards

The following safeguards are listed in order of effectiveness, from most effective to lease effective, according to OSHA’s hierarchy of controls.

Need an easy to print cheat sheet that contains all of this information? Check out our printable Band Saw Safety Guide.

Engineering Controls

- Install an interlocked motor brake to stop the blade quickly after each operation [OSHA 1910.212(a)(1)].

- Install accidental restart prevention [1910.213(b)(3].

- Install an ANSI-compliant emergency stop button [NFPA 79].

- Use approved lockout/tagout means and procedures for all maintenance activities [OSHA 1910.147].

- Fully guard or enclose all portions of the saw blade, except for the working portion of the blade between the bottom of the blade guard guide rolls and the table [OSHA 1910.213(i)(1)]. This includes guarding or enclosing any exposed blade under the table.

- Fully enclose all pulley mechanisms and rotating components [OSHA 1910.219(d)].

- (if dust is generated) Provide interlocked dust collectors or powered exhausts [OSHA 1910.94(b)(2)].

Administrative Controls

- Use fences, jigs, and push sticks during cutting operations to provide distance between the operator and any point of operation or nip point hazards.

- Properly adjust the height of the blade guard before every cutting operation [OSHA 1910.213(i)(1)].

- (if an OEM foot brake is installed) Bring the saw blade to a controlled stop before the operator leaves or reaches near the blade [OSHA 1910.212(a)(1)].

Personal Protective Equipment (PPE)

- Wear eye protection.

- Wear any other PPE appropriate for the task.

An All-In-One Solution

The MAKESafe Power Tool Brake is a plug-and-play braking solution that also includes anti-restart and emergency stop. All you have to do is plug it in, perform a calibration that takes less than five minutes, and you’ve added multiple machine safeguards to your band saw. See the product demonstration video and specifications for more information.

Scope: The information above is intended for standard vertical and horizontal band saws. Additional requirements for resaw and automatic-feed band saws are not included.