[This article was revised on December 17th, 2018 to incorporate feedback from John ”Grizzy” Grzywacz, professor Emeritus from the OSHA National Training Institute and OSHA compliance officer trainer[i]. Original posting in September of 2018.]

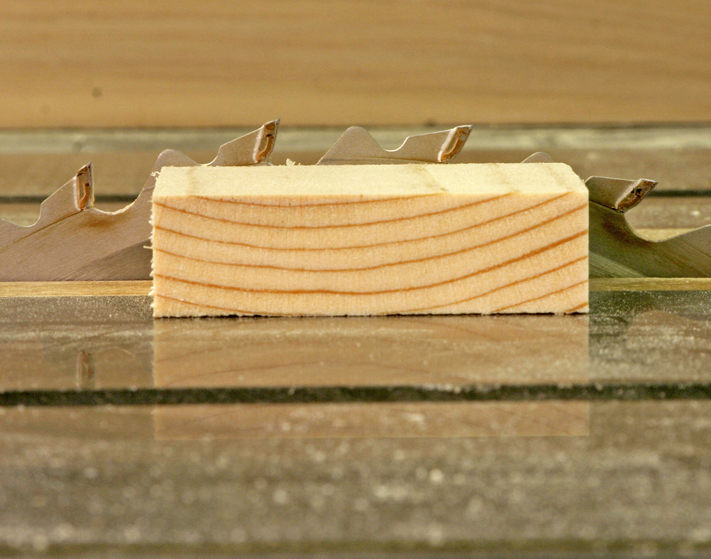

Operators of high-inertia, low-horsepower (HILHO) machines are at great risk of injury. The Bureau of Labor Statistics reports that in 2017, 156 workers died and more than 36,000 workers went home with amputations, lacerations, and other traumatic injuries as a direct result of contact with industrial machinery. Include injuries that were not reported or did not result in missed days from work and our preliminary data shows that 1 in 4 machine operators have first or second hand experience with lacerations or distal finger amputations as a result of HILHO machinery. Recent research in the table saw industry, as part of the CPSC proposed rulemaking for active injury mitigation devices, estimates that there were over 9.5 million table saws in use in 2007/2008 and that that there are over 260,000 unique companies in industries using table saws. An extrapolation of that estimate to include other HILHO machinery and industries outside of woodworking yields in excess of 20 million HILHO machines currently in use in the United States.

OSHA Standards

“One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are-barrier guards, two-hand tripping devices,electronic safety devices, etc.” [OSHA 1910.212(a)(1), General requirements for all machines.]

The industry is aware of the scope of this risk and requires machine safeguards on all machinery. However, point of operation guarding has been one of OSHA’s ‘Top 10 Most Frequently Cited Standards’ for over a decade. One significant contributing factors to this high rate of citation is the ease of enforceability. The absence of machine safeguards is often visible at a glance, especially if the machine is being operated at the time of inspection. That makes it easy for OSHA to identify the violation and is an effective way for them to reduce everyday risk in the workplace. Another significant contributing factor to the high citation rate is the unexpected complexity of effective machine safeguarding. Many in the industry mistakenly believe that blade guards and chip shields are, in and of themselves, an effective machine safeguard when in fact they are just one piece of the puzzle. Point of operation hazard mitigation can be especially complex since it is required to be “… designed and constructed as to prevent the operator from having any part of his body in the danger zone during the operating cycle”[OSHA 1910.212(a)(3)(ii)]. Many machine operations require the retrieval, adjustment, or measurement of a workpiece between cutting operations and that often means that an operator is displacing a machine guard to reach near the point of operation. If the machine in use has significant inertia then the point of operation (blade, abrasive disc, etc.) may still be spinning and classified as a hazard. If an operator is not protected from this hazard then it is an OSHA citable offense.

But how often do injuries occur during workpiece measurement or retrieval? The US Department of Labor determined that roughly 18% of circular saw injuries (inclusive of table saws, radial arm saws, etc.) occur when “… the operator touched or moved his hand into the blade while he was removing materials from the saw table[iii].” While this data is specific to circular saws, it can reasonably be extrapolated to the consideration that a significant percentage of injuries sustained by machine operators occur during the retrieval, measurement, or adjustment of a workpiece. As mentioned previously, this aspect of machine safeguards is often neglected by safety professionals, represents a significant hazard to operators, and is an OSHA citable offense.

What Machines are Most At Risk?

While machine safeguard requirements apply to all machines (including those covered by machine-specific vertical standards), MAKESafe Tools has identified one class of machines that has been generally neglected and is lacking in adequate safeguards – high inertia, low horsepower (HILHO) machines. HILHO machines are typically single phase 120 or 240 volt machinery under 5HP and include band saws, table saws, bench grinders, lathes, and sanders or polishing equipment. The rotating element of HILHO machines – be it an arbor, cutting tool, blade, or flywheel – have significant inertial mass that cause the rotating element to continue to spin long after the device has been switched off. In the case of a band saw or table saw, this means that the blade continues to be a hazard long after the machine operation has completed. As shown in Table 1, machinery can coast for as long as two minutes when switched off, putting an operator at risk when they reach in to retrieve, measure, or adjust their workpiece.

| Brand | Type | Horsepower | Coasting Time (mm:ss) |

|---|---|---|---|

| Delta | Bench Grinder | ½ | 1:59 |

| Laguna | Bandsaw | 1 ¾ | 1:03 |

| Powermatic | Table Saw | 3 | 0:20 |

| Central Machinery | Disc Sander | 1 ½ | 1:16 |

| Dewalt | Bench Grinder | ⅝ | 1:41 |

Table 1 – Coasting Times

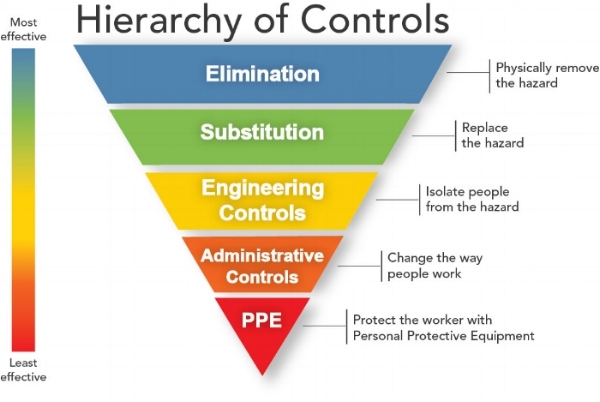

This gap in machine safeguards warrants the development of proper engineering controls. As stated in OSHA’s recommendations for “Hazard Prevention and Control”, engineering controls are a more effective safety means when compared to Personal Protective Equipment (PPE) like barrier guards (see Figure 1)[iv]. In fact, OSHA recommends a specific engineering control solution to this coasting problem – the installation of a braking device to quickly stop the spinning hazard at the conclusion of each operation[v].

Figure 1 – OSHA’s Hierarchy of Controls

Mechanical Machine Braking

Machine braking can be achieved in two ways. First, machines can be braked mechanically by applying friction between a brake pad and a rotating element of the machine.

Manufacturer-provided mechanical machine braking methods are commercially available in a limited number of HILHO machine types and are, when implemented well, capable of significantly reducing coasting times and reducing operator risk. However, the commercial availability of mechanical braking for HILHO machines is limited and they are not not practical to retrofit to existing machines.

Electrical Motor Braking

Electronic motor brakes use DC injection, plugging, or capacitive braking to apply a braking torque to a machine through its existing electric motor. Electronic motor brakes are commercially available for machinery above 5HP but their commercial availability for HILHO machines is limited and their integration into existing machinery requires a cost and complexity well in excess of the perceived value. For example, an installation of an electronic brake on a band saw in the current market would require the following: (1) knowledge that motor braking is a potential machine safeguard, (2) identification of motor type (i.e. induction vs. universal), number of phases, voltage, and horse power, (3) significant research into, and procurement of, a motor braking module and other required contactors, switches, and enclosures (a nontrivial task), (4) a complete redesign of the machine control system and operating procedures, (5) the installation of the new enclosure and controls by a qualified electrician, including modification of all manufacturer-provided switches and wiring, (6) field certification of the control system by a nationally recognized test lab (NRTL), and (7) retraining of all machine operators. With time and expense considered, the cost of these modifications can be more than five times the cost of the band saw itself. MAKESafe Tools categorizes this as a prohibitively complex procurement and installation option. Despite the inherent benefits of the solution, the cost and complexity of the intervention outweighs the benefit, rendering it not reasonable for most businesses.

Introducing The MAKESafe Power Tool Brake

MAKESafe Tools was founded to solve problems just like this – problems at the intersection of usability and engineering controls. It is our mission to identify or develop high performance machine safeguards and to make them accessible and affordable for every business.

When MAKESafe Tools first identified motor braking as a high performance machine safeguard, we patended and developed an electronic motor braking and safe start device that can be installed on any HILHO machine as a “plug and play” device by any machine operator or layperson with no specialized training and without any machine modification. This technology was developed on the hypothesis that the complexity of high performance machine safeguard procurement and installation is a significant barrier to compliance and operator safety for HILHO machines. The 120V single phase motor brake, for use with stationary equipment up to 1.5HP, is available now and you can request a quote here.

We are also working with the National Institute of Occupational Safety & Health to continue our study of machine safeguards. To learn more about our proposed research or our products, please contact us via our website at www.makesafetools.com.

End Notes

[i] More information about John Grzywacz can be found on his website at http://oshaprofessor.com.

[iii] Woodworking Circular Saw Accidents, US Department of Labor Bulletin 1190, 1956

[iv] UNITED STATES DEPARTMENT OF LABOR. Occupational Safety and Health Administration. URL: https://www.osha.gov/shpguidelines/hazard-prevention.html (Accessed September 4, 2018).

[v] Machine Guarding eTool | Saws – Table Saws. Occupational Safety and Health Administration. URL: https://www.osha.gov/SLTC/etools/machineguarding/saws/tablesaws.html (Accessed September 4, 2018).